Colorno, November 6th, 2025. Transfer Oil presents a video series exploring the capabilities and applications of Helix® thermoplastic hoses for Ultra High Pressure (UHP). Through conversations with Transfer Oil professionals involved in Helix® production and market development, this series highlights every important operation behind these hoses and their function in critical applications.

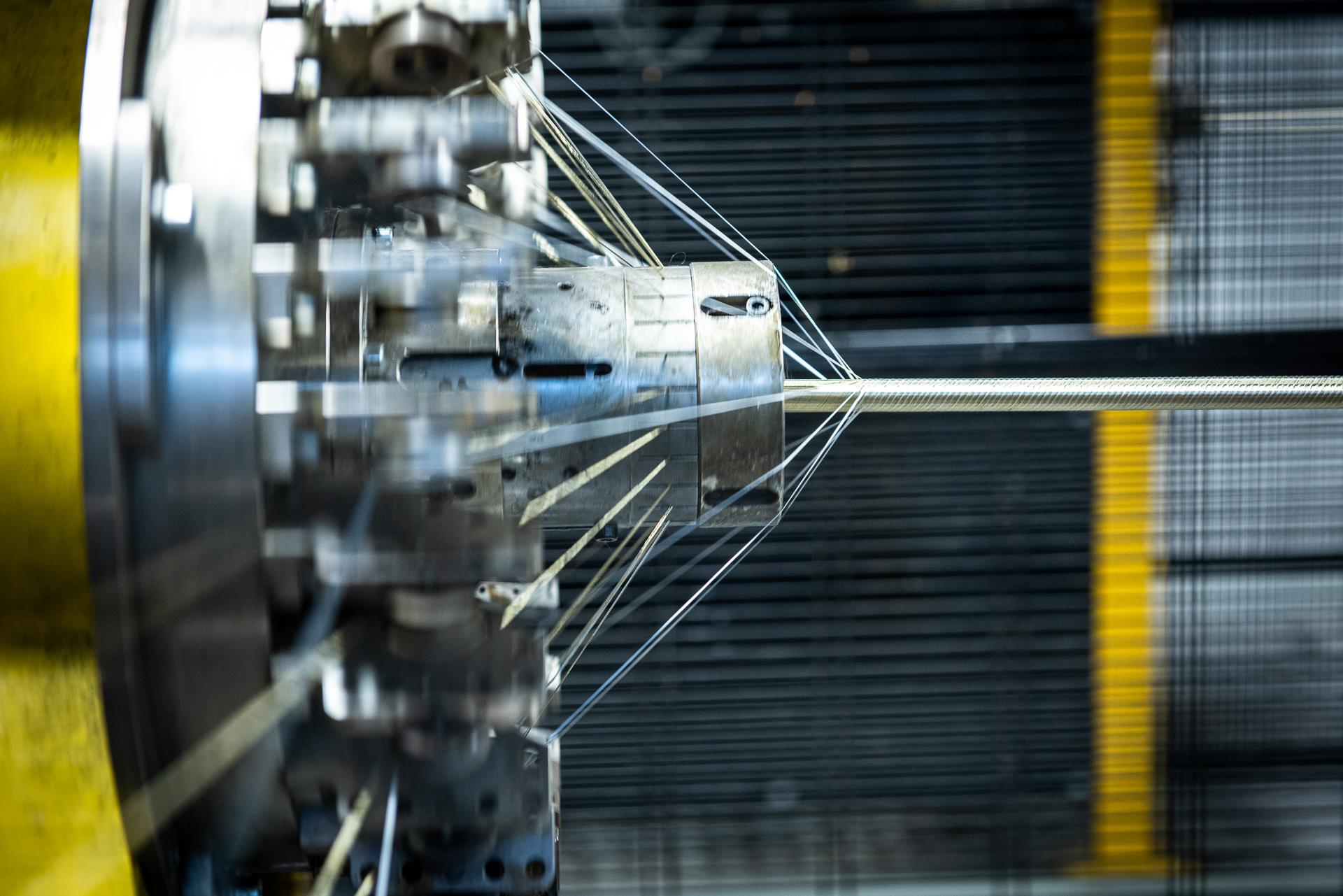

The Helix® video series begins with Ugo Ferrari, CEO of Transfer Oil, who tells about the company’s journey. Since its foundation, Transfer Oil has been dedicated to producing reinforced hoses for high-pressure applications. Ugo Ferrari highlights the development of the Helix® range, the multispiral thermoplastic hoses introduced in 2015, which now handle pressures up to 55,000 PSI (3,800 bar).

"With Helix®, we wanted to create a distinct identity for our UHP range, ensuring pressure performance, safety, and versatility," explains Ugo Ferrari.

The second video features Ali Hassan Zafar, operator of the assembly line, and Maurizio Romano, Sales Area Manager, who dive into the features that make Helix® hoses stand out.

In the third video, Andrea Monari, R&D Manager, and Marcello Romenghi, QHSE Manager, discuss Transfer Oil’s dedication to innovation.

Andrea Monari highlights how advancements in materials and design have allowed Helix® hoses to reach unprecedented burst pressures of up to 9,000 bar while Marcello Romenghi emphasizes the importance of precision in assembly and quality control. In fact, every Helix® hose assembly meets the highest safety standards, whether produced in Transfer Oil headquarters or at authorized assembly centers worldwide.

Explore the Helix® range and stay tuned on LinkedIn for more insights.

The Helix® video series begins with Ugo Ferrari, CEO of Transfer Oil, who tells about the company’s journey. Since its foundation, Transfer Oil has been dedicated to producing reinforced hoses for high-pressure applications. Ugo Ferrari highlights the development of the Helix® range, the multispiral thermoplastic hoses introduced in 2015, which now handle pressures up to 55,000 PSI (3,800 bar).

"With Helix®, we wanted to create a distinct identity for our UHP range, ensuring pressure performance, safety, and versatility," explains Ugo Ferrari.

The second video features Ali Hassan Zafar, operator of the assembly line, and Maurizio Romano, Sales Area Manager, who dive into the features that make Helix® hoses stand out.

- Rigorous testing: every Helix® hose undergoes extensive testing, from raw materials to the final assembly, ensuring 100% safety and quality.

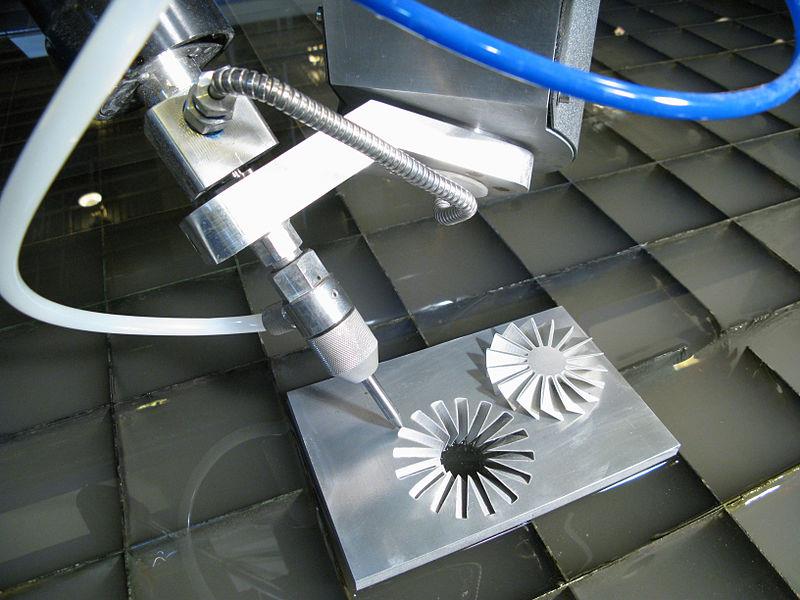

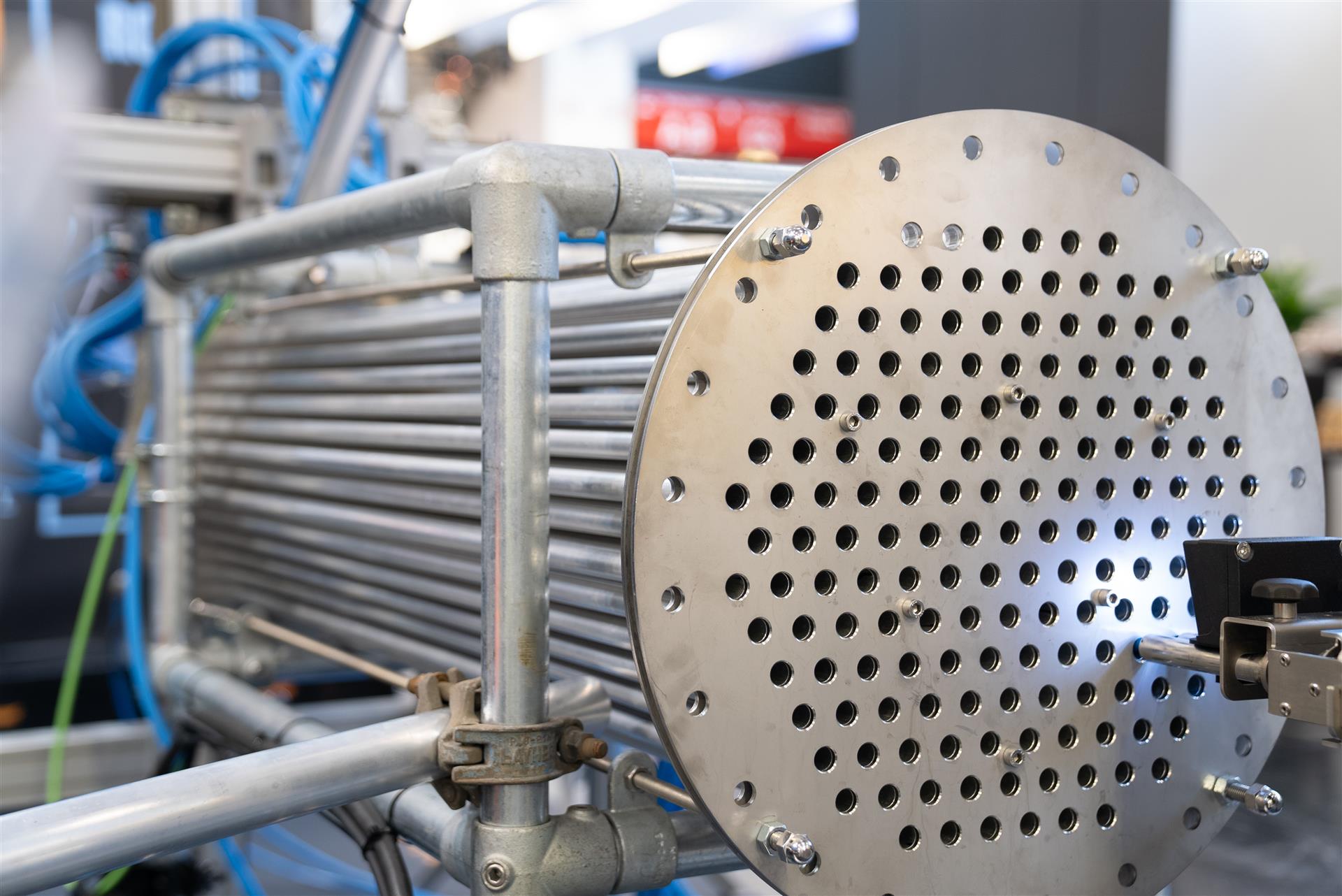

- Applications and accessories: the Helix® range serves specialized applications such as tube cleaning, hydro demolition, and paint removal. Accessories like protection jackets, stainless steel catch rings, and hose arrestors enhance safety and usability.

In the third video, Andrea Monari, R&D Manager, and Marcello Romenghi, QHSE Manager, discuss Transfer Oil’s dedication to innovation.

Andrea Monari highlights how advancements in materials and design have allowed Helix® hoses to reach unprecedented burst pressures of up to 9,000 bar while Marcello Romenghi emphasizes the importance of precision in assembly and quality control. In fact, every Helix® hose assembly meets the highest safety standards, whether produced in Transfer Oil headquarters or at authorized assembly centers worldwide.

Explore the Helix® range and stay tuned on LinkedIn for more insights.

.jpg)

.jpg)