-

-

Transfer Oil achieves EcoVadis Silver Medal11 Nov 2025

-

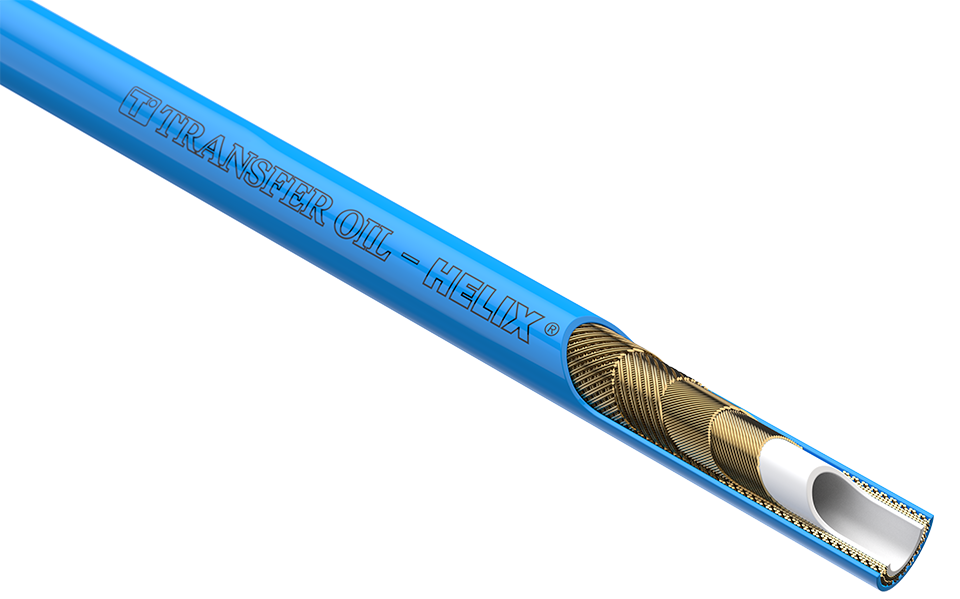

Inside the Helix® range05 Nov 2025

-

Transfer Oil at GIS Expo exhibition30 Sep 2025

-

Sustainability Report05 Jun 2025

Thermoplastic Hoses Manufacturer Since 1979

High-performance Solutions for Hydraulic, Industrial, and UHP Applications

Transfer Oil is a leading Italian manufacturer of reinforced thermoplastic hoses, fittings and hose assemblies engineered for demanding applications. Since 1979, we have specialized in the design, production, and testing of high-pressure hoses – with applications ranging from hydraulic systems to industrial fluid and gas conveying, as well as ultra high-pressure (UHP) equipment.

Committed from the beginning to the highest standards of quality and performance, Transfer Oil was one of the first companies in the industry to achieve UNI EN ISO 9001 certification in 1993. Today, our products hold globally recognized third-party certifications and approvals from organizations such as DNV (Det Norske Veritas), ABS (American Bureau of Shipping), MSHA (Mine Safety and Health Administration), and CSA (Canadian Standards Association).

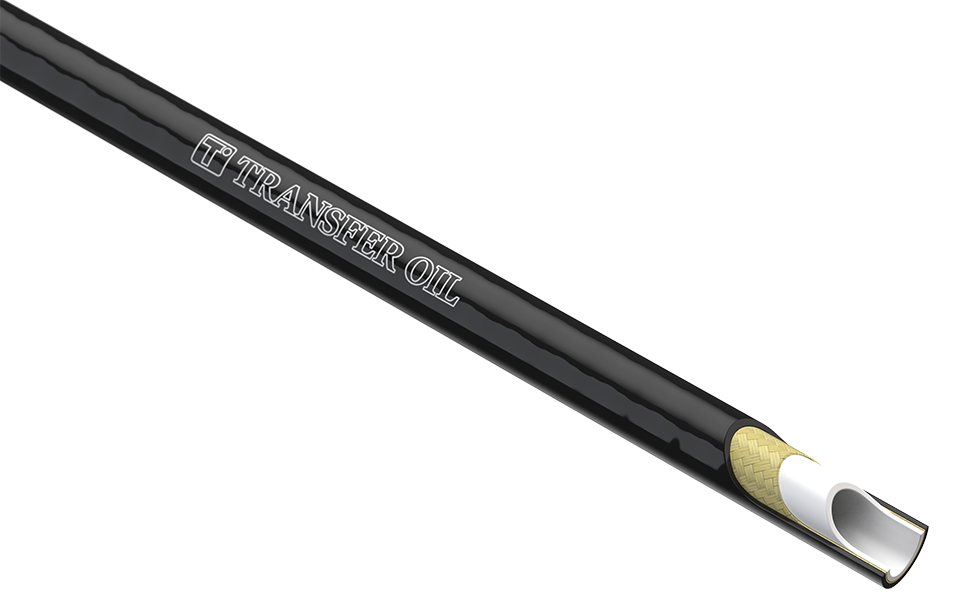

Our comprehensive product portfolio is the result of continuous research and development, offering solutions tailored to meet the needs of the most demanding industries. The TO Hydraulic range includes SAE 100 R7 and SAE 100 R8 hoses with polyurethane covers, MSHA-approved, for enhanced abrasion resistance and very low volumetric expansion for precise operation in tough conditions.

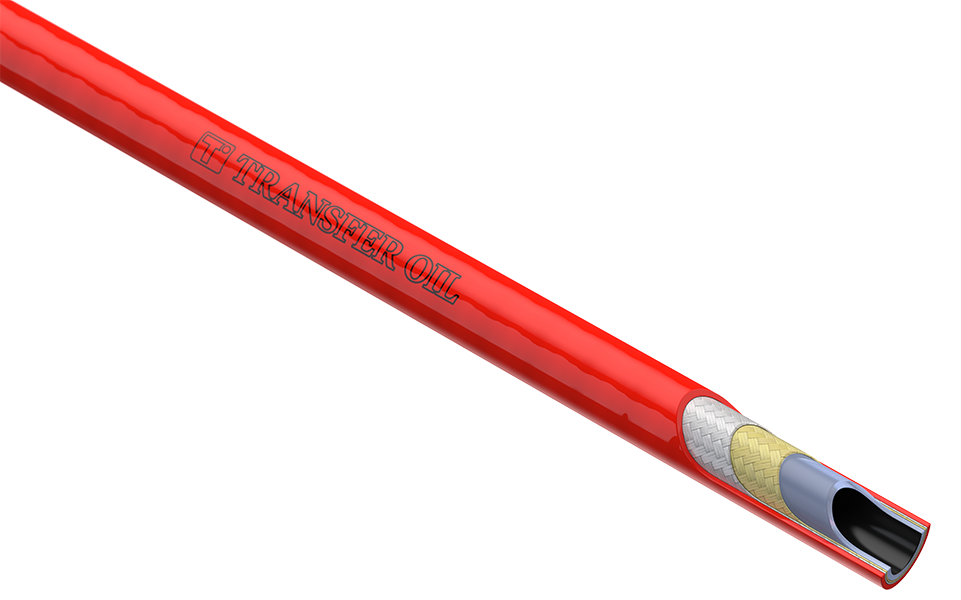

Expanding our technology into new markets, the Fuel line within our TO Industrial range supports the global transition to low-carbon mobility by offering specific thermoplastic hose solutions for clean refueling applications. We supply CSA-certified CNG hoses and hydrogen hoses both engineered for low permeability and ease of handling to ensure fast and safe refueling. Designed to meet the requirements of modern hydrogen infrastructure, our H2 hoses meet test requirements of ISO 19880-5 and are reinforced with steel and aramid fibers to withstand pressures up to 1.040 bar (15,000 psi).

For extreme pressure applications, our proprietary Helix® hose line – launched in 2015 – provides performance from 690 bar (10,000 psi) to 3.800 bar (55,000 psi), ensuring safety and durability in critical operations such as hydro-demolition, water jetting, bolt tensioning, heat exchanger cleaning and pressure testing. All Helix® assemblies are provided as factory-made assemblies only, to guarantee full compatibility and compliance with the most stringent industry standards.

With over four decades of experience, state-of-the-art facilities, and full control of every production stage – from raw materials to 100% final testing – Transfer Oil delivers thermoplastic hoses that combine innovation, quality, and performance, serving customers in more than 75 countries worldwide.