Transfer Oil is an Italian company that ranks among the most important manufacturers of reinforced thermoplastic hoses in its industry.

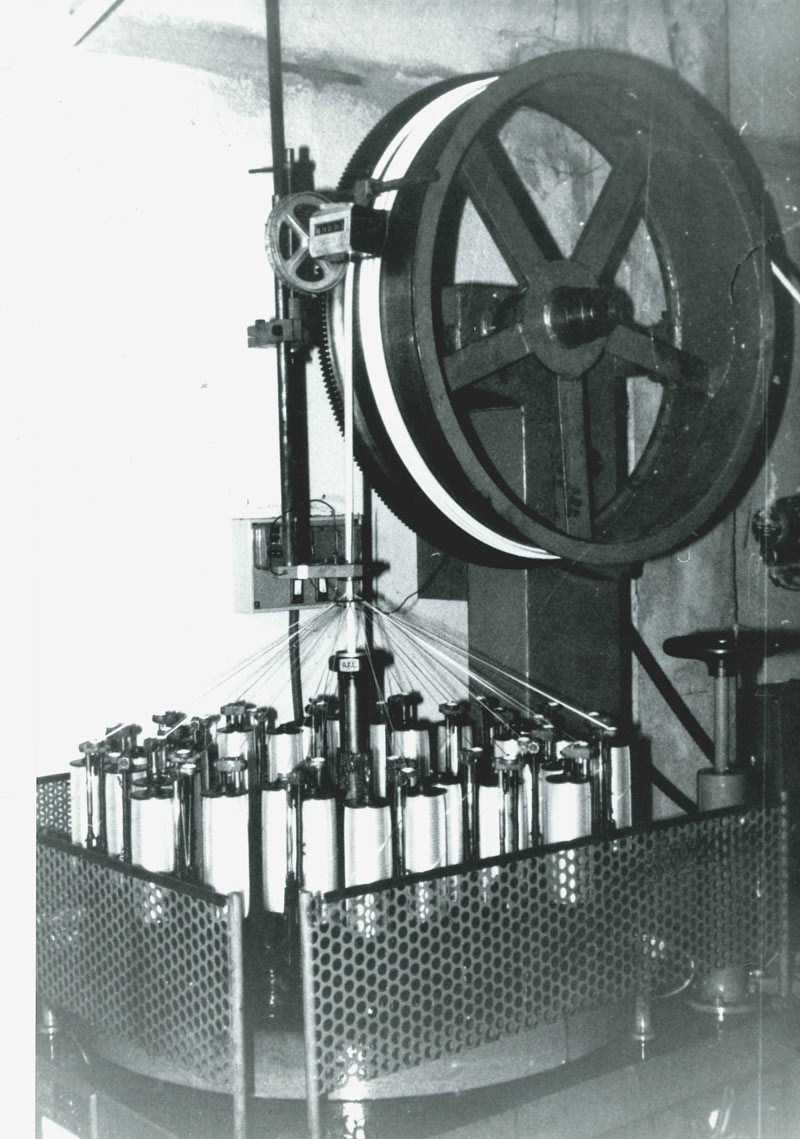

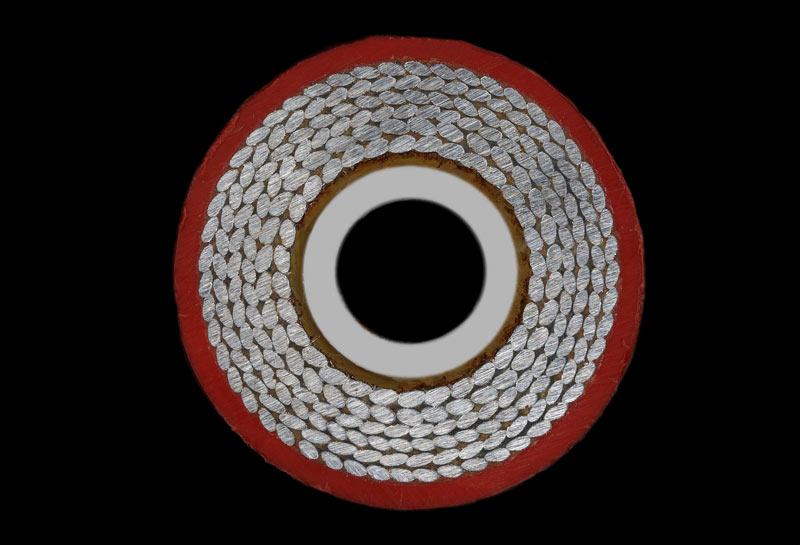

Since its beginning, Transfer Oil has produced reinforced thermoplastic hoses manufactured from the finest raw materials sourced from leading suppliers of premium engineering polymers and fibers. Transfer Oil products are the choice of the leading distributors in our field as well as renowned OEMs, which can take great advantage of Transfer Oil direct product design capability, in-house hose analysis and qualification.

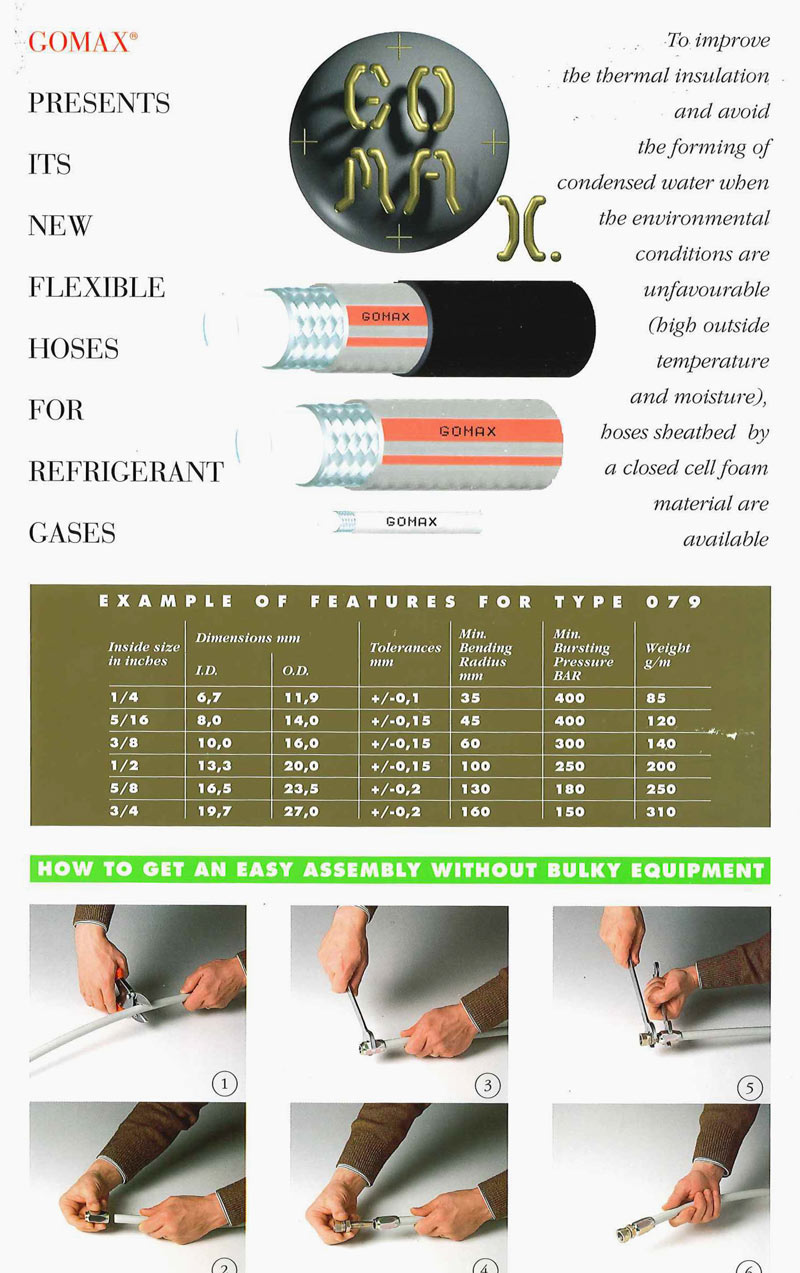

With applications ranging from hydraulic systems, gas and fluid handling, up to refrigeration and air conditioning, Transfer Oil products are used in several different industries.

Being able to assemble and proof test Ultra High-Pressure products up to 3,800 bar / 55,000 psi, Transfer Oil is today the only independent hose manufacturer able to offer the market products covering virtually every pressure range that a thermoplastic hose can reach with the technology known today.

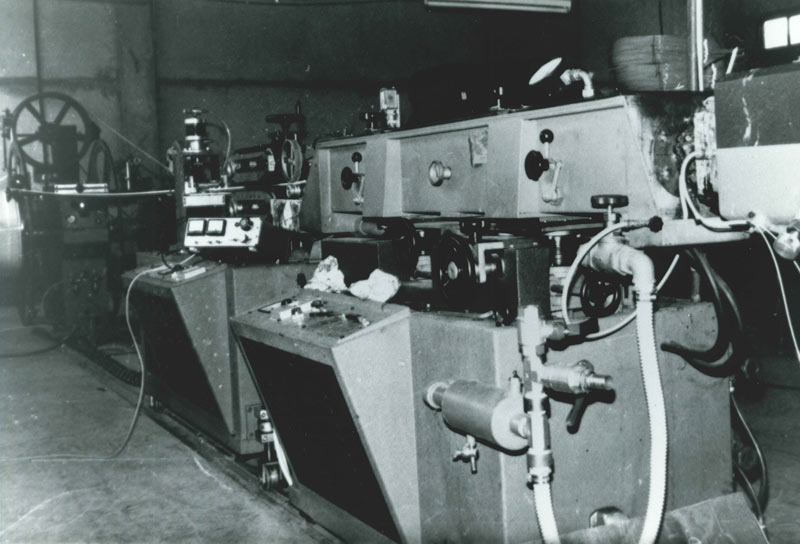

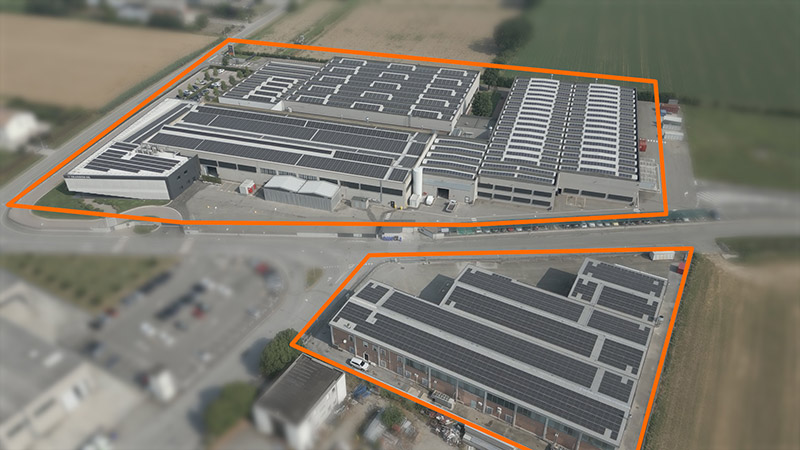

With a distinctive dedication to high technology, Transfer Oil products are manufactured in state-of-the-art facilities where health and safety, environment and quality are taken to the highest level.