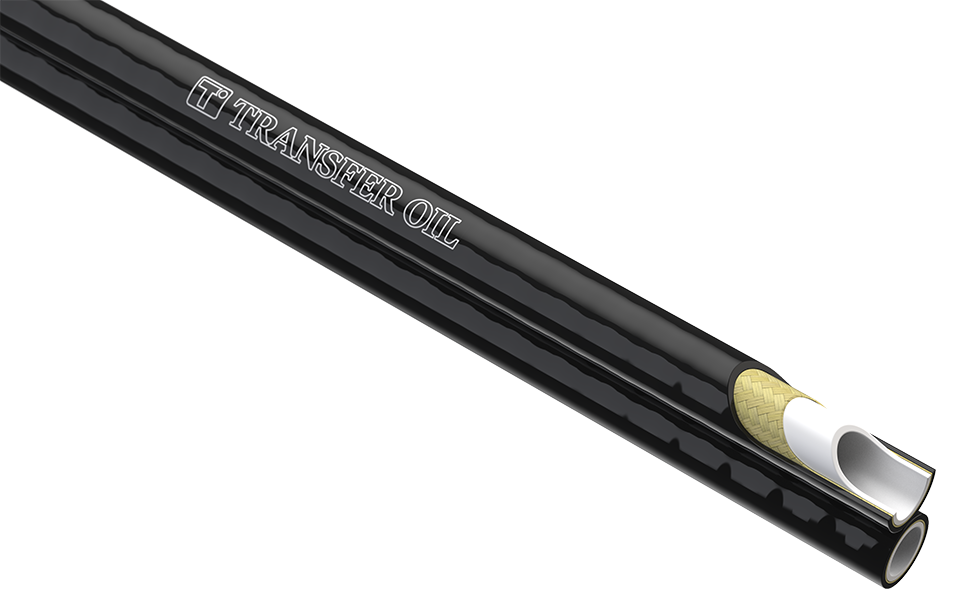

TWIN HOSE

Transfer Oil's Twin Hose solutions are the result of joining two or more hoses by means of a procedure that is unique in the industry and that does not compromise hose integrity.

The joining process can connect hoses of the same size and specification or different hose types and sizes, as well as electrical cables and wires.